The Bearhawk fuel system is gravity fed with no fuel pumps. As I previously mentioned I took great care to make sure there were no 90 degree turns in the fuel lines and that everything went smoothly continuously downhill. So now is the moment of truth. How good did I do?

The fuel flow testing was done in accordance with the 14 CFR 23.955. Here are the criteria:

1. Place the aircraft with a nose high attitude that exceeds its maximum climb angle plus 5 degrees (the 5 degrees is the assumed angle of attack).

2. Put minimal fuel in the tanks.

3. Take the fuel supply hose loose at the carburetor and prop it up at the same level as the carburetor inlet.

4. The measured fuel flow should be at least 150% (125% if you have a fuel pump system) of the takeoff fuel consumption for the engine.

Russ Erb did a lot of the calculating on this. According to his numbers the fuselage should be placed at about 19 degrees nose up attitude.

So what is 150% of takeoff fuel consumption? My O-540 has a BSCF of .50 at full take off power. So the math looks like this:

.50 BSFC x 260 HP / 6 = 21.6 GPH x 150% = 32.5 GPH

So the engine for this Bearhawk drinks 21.6 gallons per hour at full takeoff power. The FAA wants to see fuel flow rates in excess of 150% of that. So 32.5 is our goal.

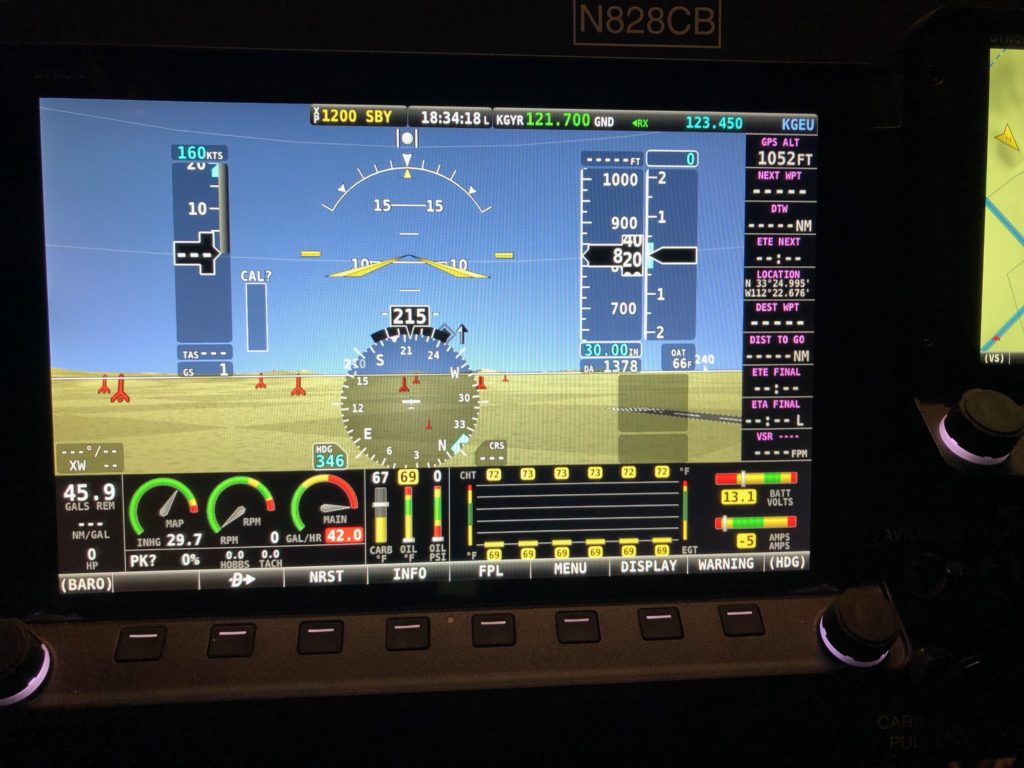

To start with, we put 2.5 gallons in each tank and did a quick fuel flow test in a 3 point attitude. Wow! 42.0 GPH looks promising! Now on to the real fuel flow test. (disregard the gallons remaining. I don’t have electronic fuel sensors and that was just a default value)

My brother and I pushed my Bearhawk to a nearby drainage ditch to put the tail in so we could attain the required 19 degrees pitch up attitude. Next we place 2.5 gallons of fuel in each tank, purged the system of air and attached gallon water jug to catch the fuel from the fuel line at the carburetor.

I flipped the fuel selector to both and timed for exactly 60 seconds at which point I flipped the fuel selector to off.

We did the procedure 5 times. Each time it was nearly the same, but we averaged the results just to be sure.

The average came in at 3 lbs 6 oz after 1 minute. That comes out to 3.38 lbs. So the math follows that 3.38 lbs x 60 minutes = 202.8 lbs. 202.8 lbs / 6 lbs per gallon = 33.8 GPH.

32.5 GPH was the goal. 33.8 GPH was our result.

So, at 5 degrees above max pitch our gravity fed fuel system is able to supply 156% of required fuel flow at max power at sea level. Talk about overkill!! But the most important thing is that it exceeds FAA guidance.