The Bearhawk normally comes with streamlined (airfoil shaped) landing gear struts. Some people have noted that in a severe ground loop the normal strut could collapse. So Mark Goldberg was kind enough to swap those out for these round ones at no additional charge.

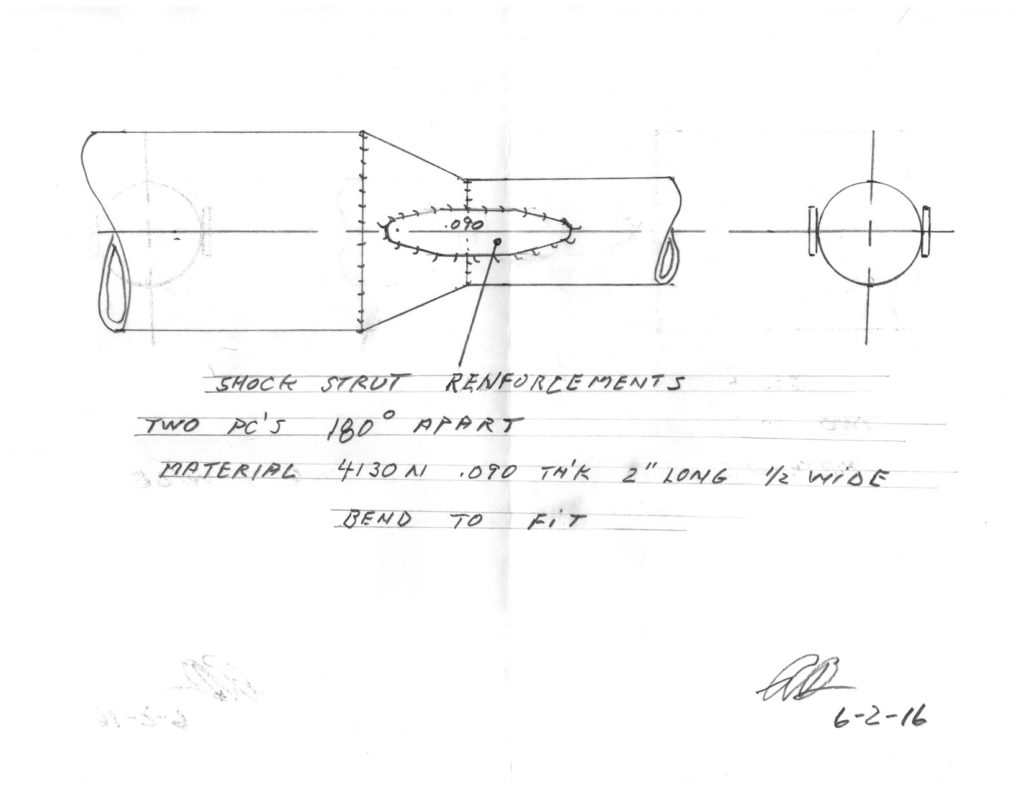

These upgraded struts will beef up the landing gear substantially! I will need to put some kind of airfoil fairing on them eventually.

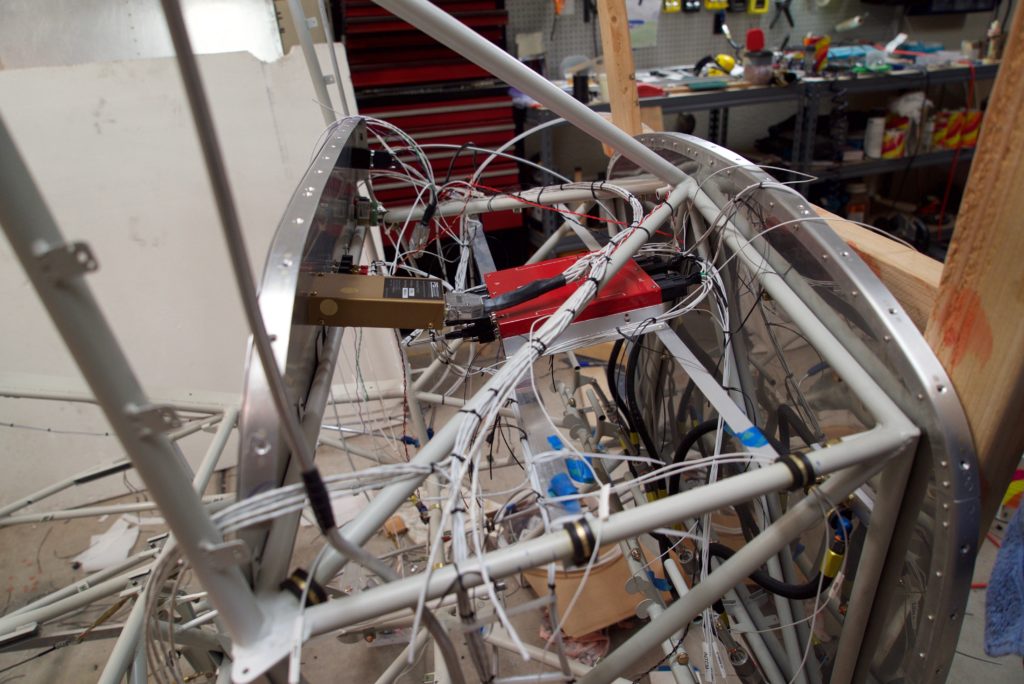

It looks pretty good sitting on it’s own landing gear now! As you can probably see, the landing gear looks rather narrow. This is because it doesn’t have full weight on wheels yet. It will eventually widen the gear an extra 10″ once full weight is on it.

The landing gear went together rather easily. The only problems I ran into was not having beefy enough retaining ring pliers and the rod ends not threading into the piston. So I had to make a quick run to AutoZone to pick up some heavy duty retaining ring pliers. Then I made a trip to Ace Hardware to pick up a tap for the threads. I had never tapped or cleaned up threads before, but EAAVideo.org has great videos for these kinds of things. The threads cleaned up nicely.