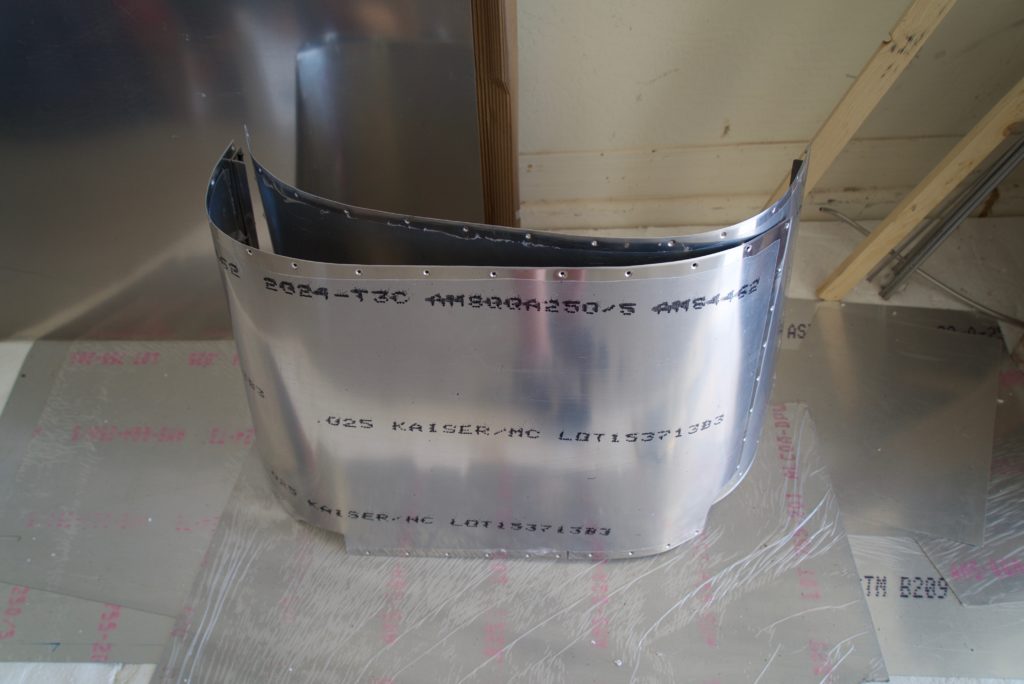

I had originally started cutting the door hinge slots in the right boot cowl side. I didn’t like the fit so I decided to use pasteboard to make a new one.

I found this little contraption at Lowes. It’s basically an upside down mounted jigsaw with a table. Brilliant!

Doing it first in pasteboard makes is so much easier to get an exact fit!

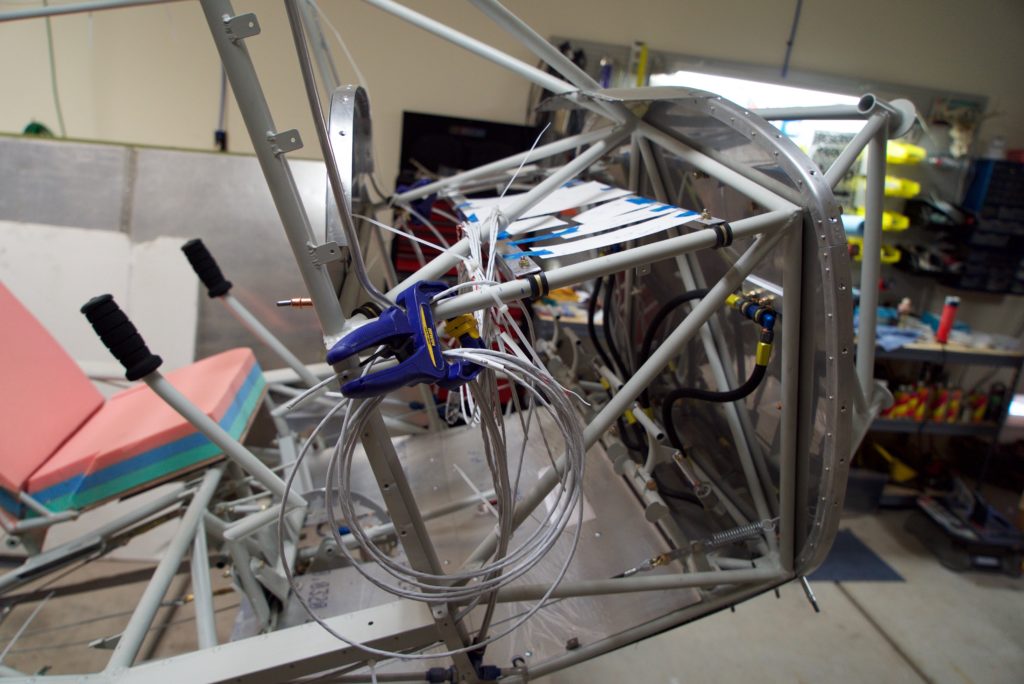

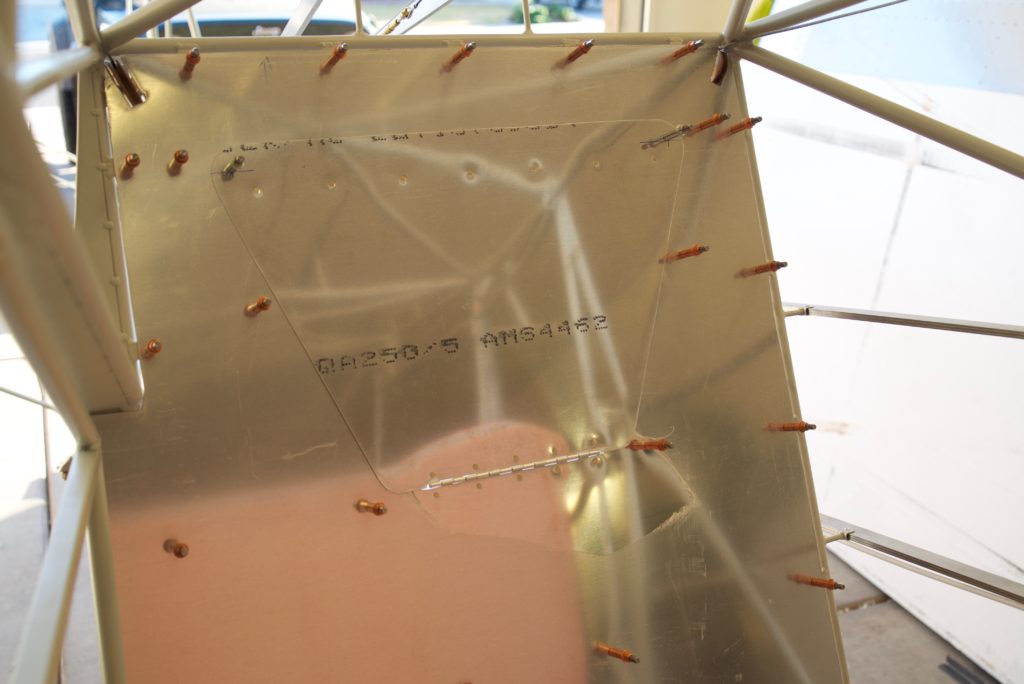

I took quite a bit of time making exactly certain that I like how everything fit before drilling any holes.

Since the top has that removable panel designed to mount flush, I attached these reinforcing strips to the seems. You can’t see it from this picture, but the far side is bent at a 90 degree angle to provide stability.

It’s starting to look more like an airplane!