Mike arrived with two Bearhawks! We only got one though.

Mike arrived with two Bearhawks! We only got one though.

My wife Cati jumped right in and took control of the situation!

My wife Cati jumped right in and took control of the situation!

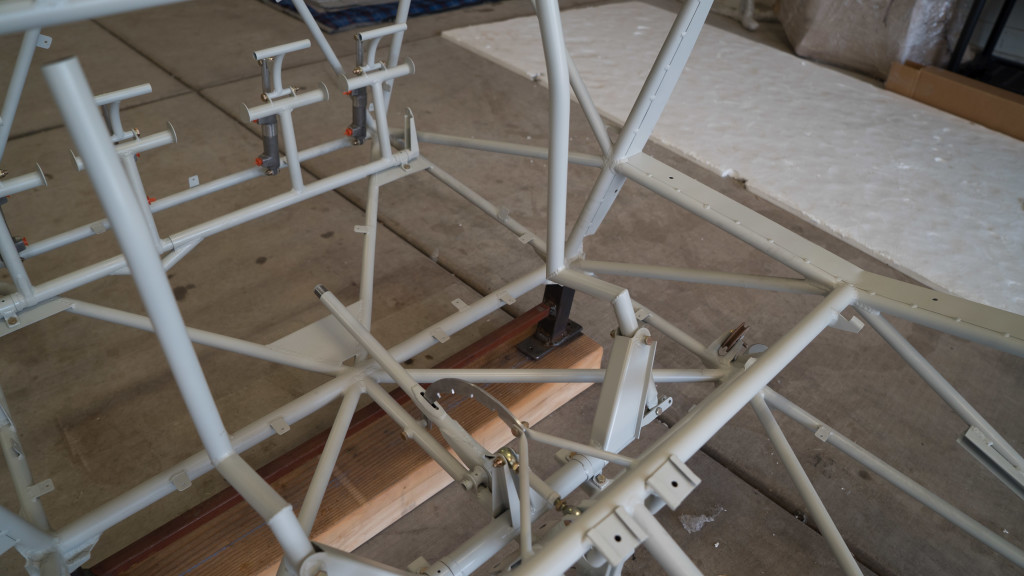

Mike made quick work of unwrapping everything for unloading. The fuselage came packed with all the parts.

Mike made quick work of unwrapping everything for unloading. The fuselage came packed with all the parts.

The wings were packaged separately in two wing crates.

The wings were packaged separately in two wing crates.

I invited my good friend Andy to help supervise. He did a marvelous job!

I invited my good friend Andy to help supervise. He did a marvelous job!

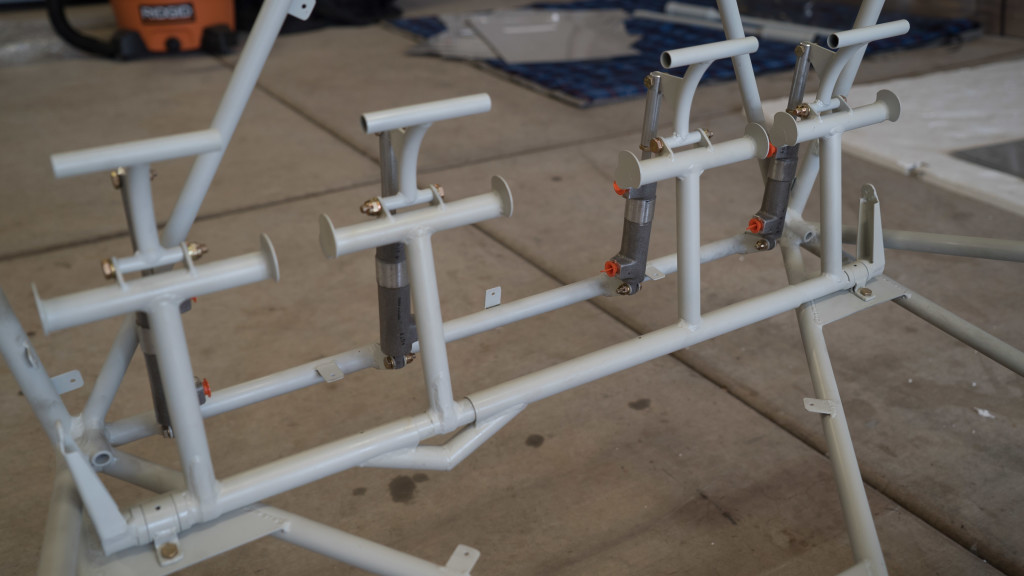

The wings were surprisingly light! I had built some EAA wing slings to hold the wings so we could return the wing crates.

The wings were surprisingly light! I had built some EAA wing slings to hold the wings so we could return the wing crates.

Cati and Tori were very happy with how everything was moving along. My oldest daughter Jessica was the one behind the camera. So no pictures of her here.

Cati and Tori were very happy with how everything was moving along. My oldest daughter Jessica was the one behind the camera. So no pictures of her here.

We loaded the empty wing crates back on the flatbed.

We loaded the empty wing crates back on the flatbed.

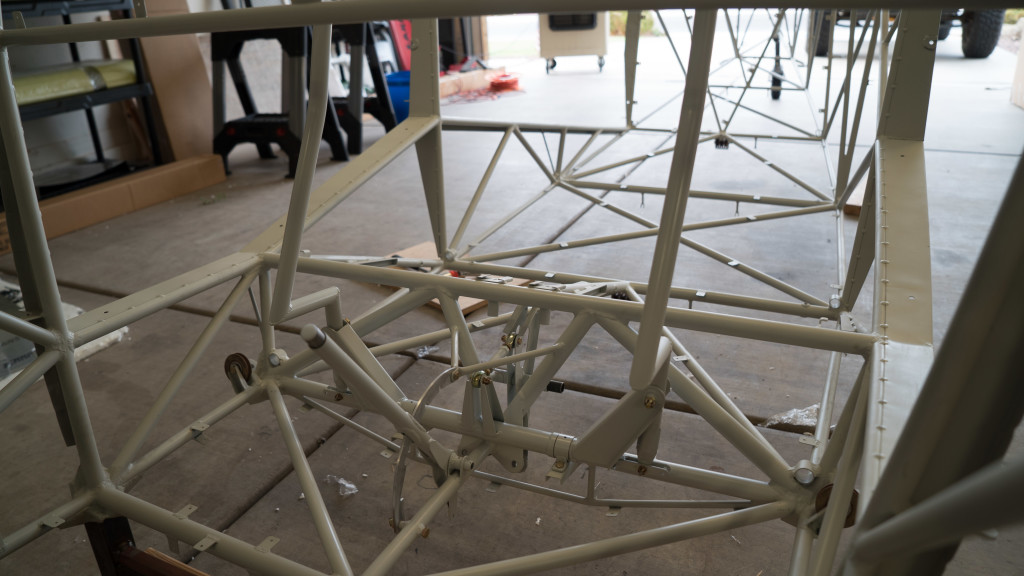

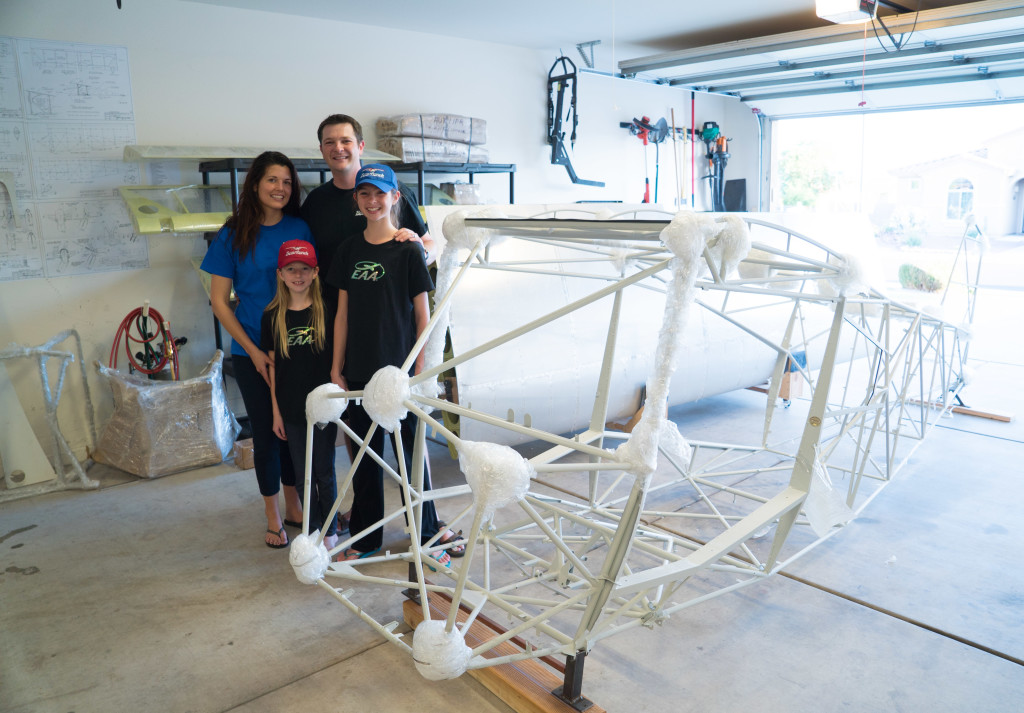

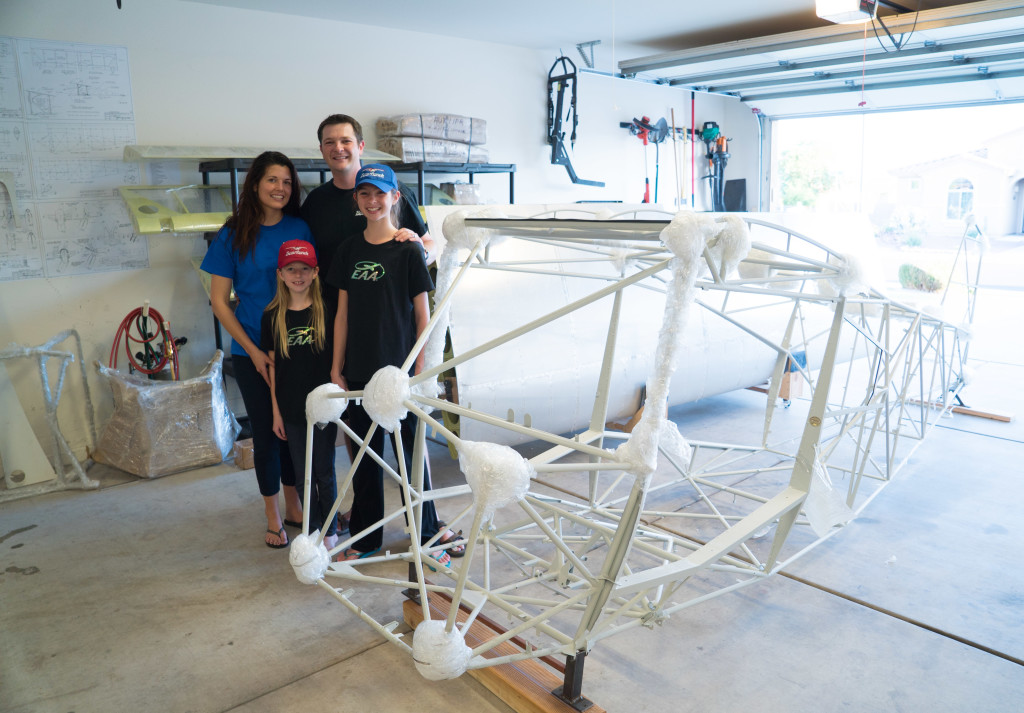

Now our garage is full of Bearhawk parts!! My whole family is really excited to get started on the project!

Now our garage is full of Bearhawk parts!! My whole family is really excited to get started on the project!

Good times were had by all!

Good times were had by all!