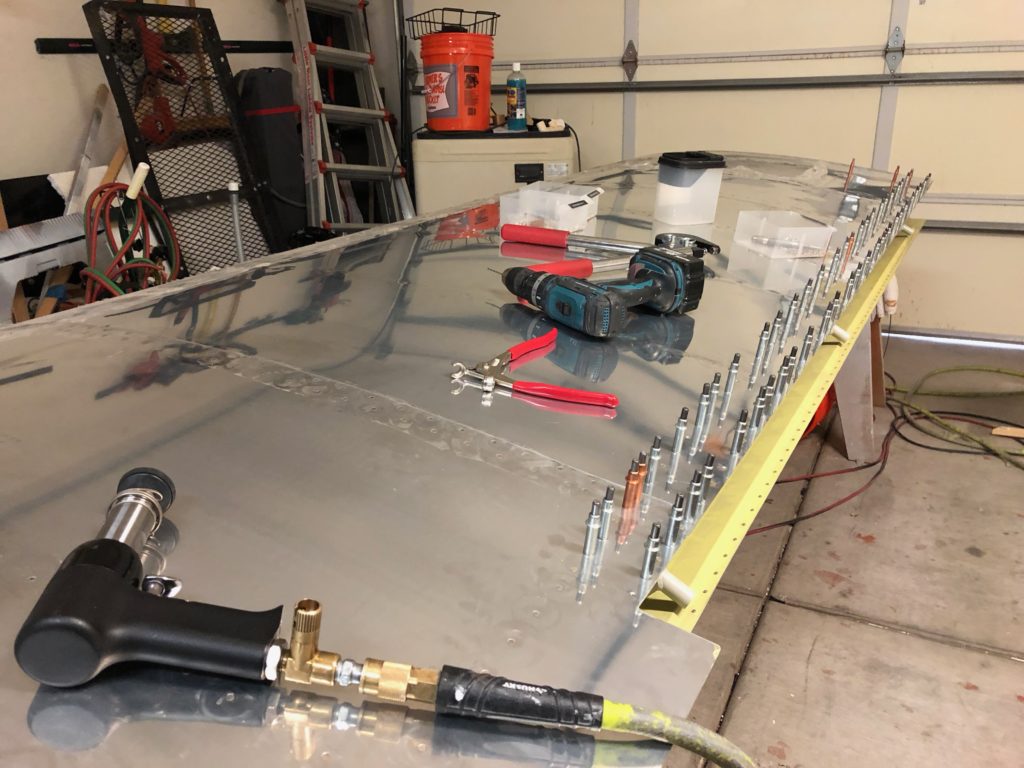

We prepped the wings with MEK, scotchbrite, metal surface cleaner and alodine. They’re now ready for paint!

First the tack coats of epoxy primer then the polytone. So far so good!

After letting the final coat dry for 7 hours I taped for the blue leading edge.

The blue paint is a bit scary. The pigment is so potent. Even one spec in the wrong place will ruin a paint job!

Remarkably it turned out great!!!!

Here they are in daylight. They look pretty good if I do say so myself!