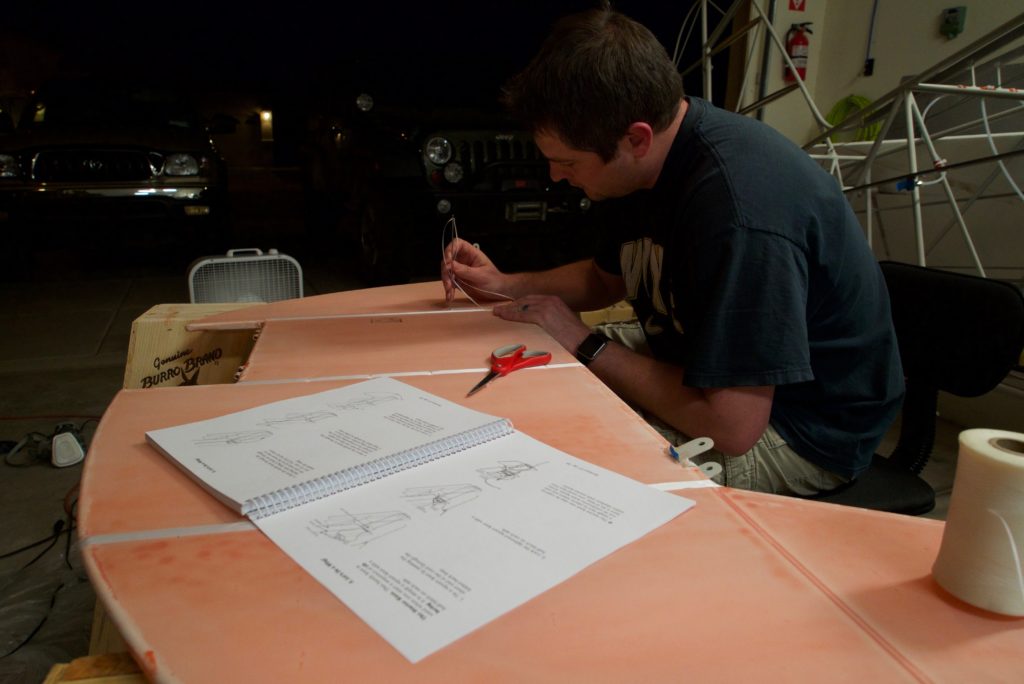

After a lot of thinking, scheming and planning, I decided on a panel layout. I started measuring everything then started figuring out how to drill square holes.

In this picture you can see the master switches, ignition switch, ELT, toggle switches and intercom have all been drilled and mounted.