Now that the fuselage is safely in the hangar it’s time to move on to the wings. I used 1×2 supports with finishing nails in them to hold the wing skin open. Worked great!

The Big Move

Moving the fuselage to the airport was seriously nerve wracking for me! I was so afraid of it getting damaged. But it went great!

I rented a Penske truck with a hydraulic lift. We placed the main wheels on the lift.

My friend Andy and I manually raised the tail.

My wife raised the lift.

After a very careful and slow drive to the airport we extracted the fuselage in reverse order. If you pay close attention, the door didn’t open all the way and it scuffed the top of the fuselage. Not bad, but needed a little paint touchup.

Success!! One fuselage in the hangar!

3rd EAA Tech Couselor Visit

Today Ron Decandia came by to do our third tech visit. Everything was good and Ron didn’t have any squawks for me.

Mouse Doors!

Throttle and Mixture Bracket

Landing Light Fiberglass

Here’s the end product! I attended a two day fiberglass class that the EAA put on. It was great and taught me the skills necessary to pull this off.

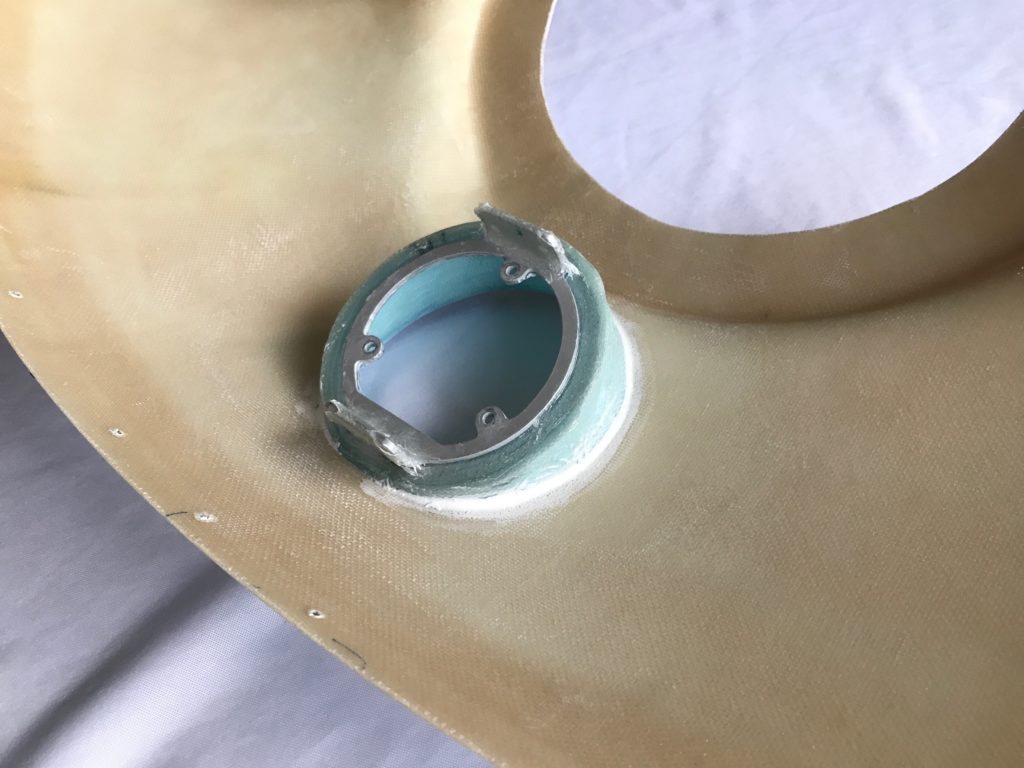

I created a fiberglass cylinder that attached to the light mount then roughly installed it in the hole I cut.

I built up the microspheres around the mount so I could fiberglass it in. I don’t have a picture of what it looked like after the fiberglass on the back, but I made sure it wasn’t going to move! 🙂

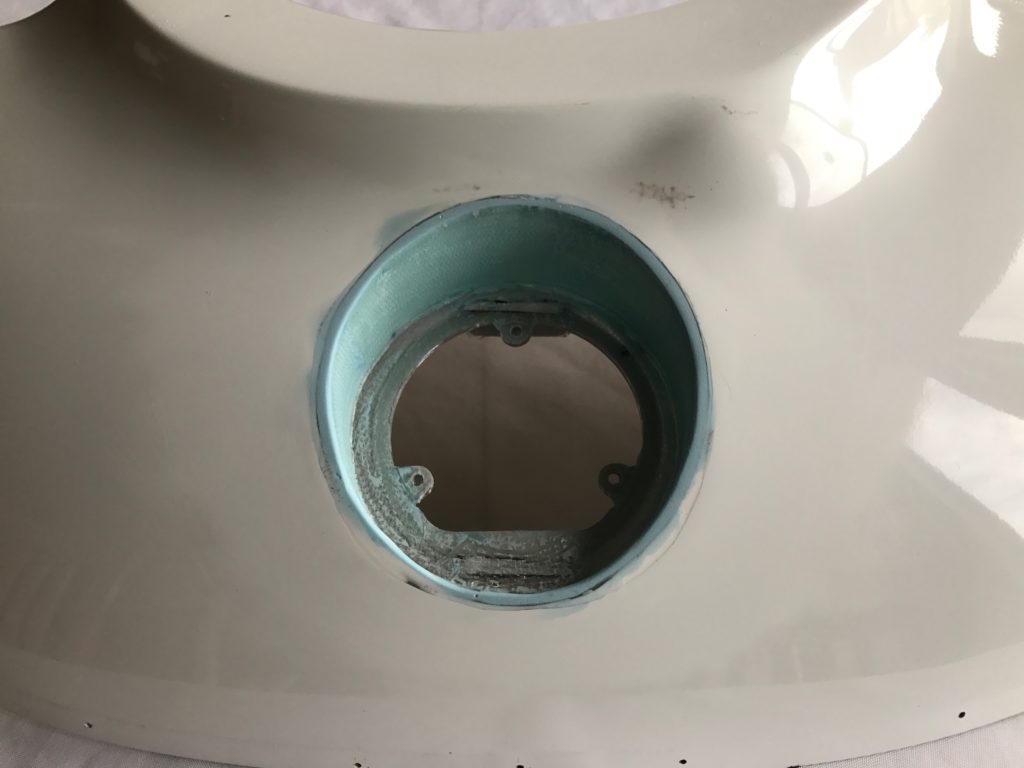

Microspheres on the front, then logs of sanding to make it all smooth.

I sprayed on a sandable primer with UV protection.

Turned out pretty good!

Bulkhead Paint

I used a new Mark III paint on the rear bulkhead. I didn’t really like it very much. I was looking for something that worked better on metal than PolyTone. The paint seeped under my masking lines and didn’t end up as crisp as I’d like. Oh, well. I could remake it if it ends up bothering me that bad.

Oil door

Airbox intake

Cowling and My Goofy Brother!

Ta dah! This is the finished product after several days of measuring, measuring, measuring and oh yeah, measuring. Then a lot of fitting then finally drilling.

Installing clecos took a very long time with Timmy. He had to strike just the right pose to get the job done.

As you can see, he was very, very, very proud of his work installing that cleco.