My brother Timmy cam out again to help me tackle another large part of the plane. This time it’s the cowling. We spent several days working on this.

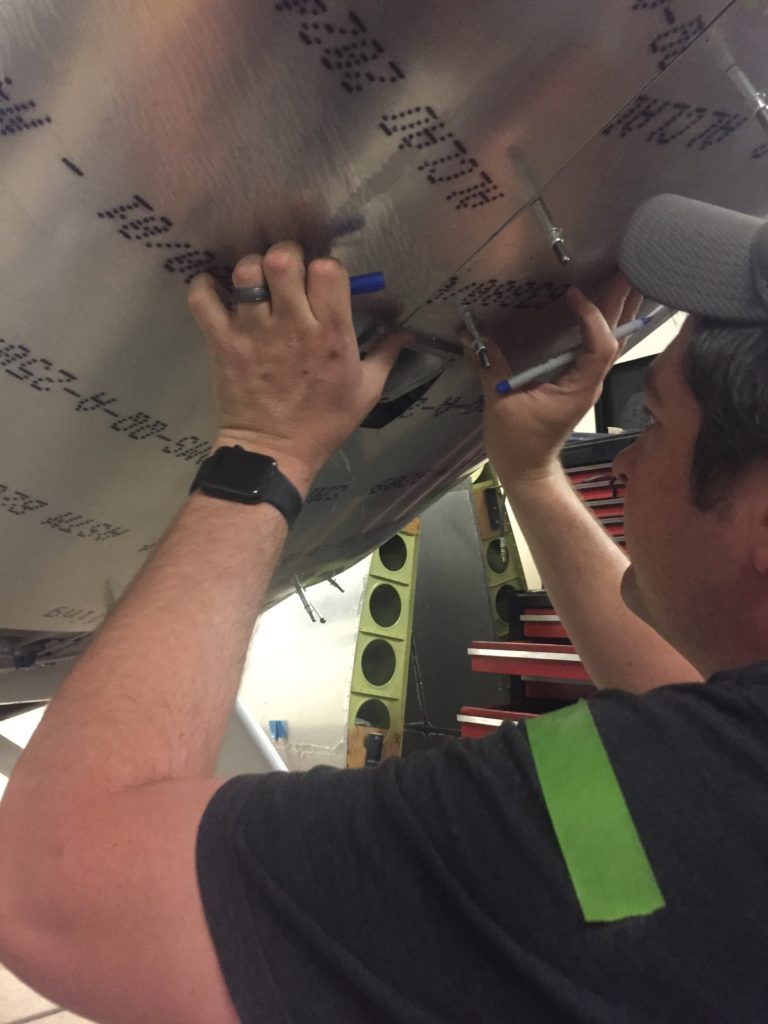

The largest part of the cowling is fitting and measuring!

Drilling the hinges for the doors was pretty easy. Yes, I was drilling over the carpet, but we cleaned up!

Trying to get everything lined up just right was a bit tough. So The method I came up with was to lay the door against the nose bowl. Then trace the edge of the nose bowl to the inside of the door.

Then we bought some masking tape that was exactly the width of the flange on the nose bowl. After putting the tape exactly on the line, I’d cut to the edge of the tape.

Worked perfectly!