Today Ron Decandia came over to do our first tech visit. He did a very thorough inspection and spent a lot of time asking me questions about how I’ve done things. He had a few very good suggestions.

Category: Bearhawk 1175 Building Log

Building log of Bearhawk 1175

Horizontal Stabs

After the paint booth was constructed, I started spraying the horizontal stabs. I started with the coats of PolyBrush then with the PolySpray. I did no more than 2 coats a day with Paint Surface Cleaner and a tac rag between coats.

After I sprayed 2 cross coats of PolySpray, I took them inside and sanded out what I din’t like. Then sprayed 3rd cross coat.

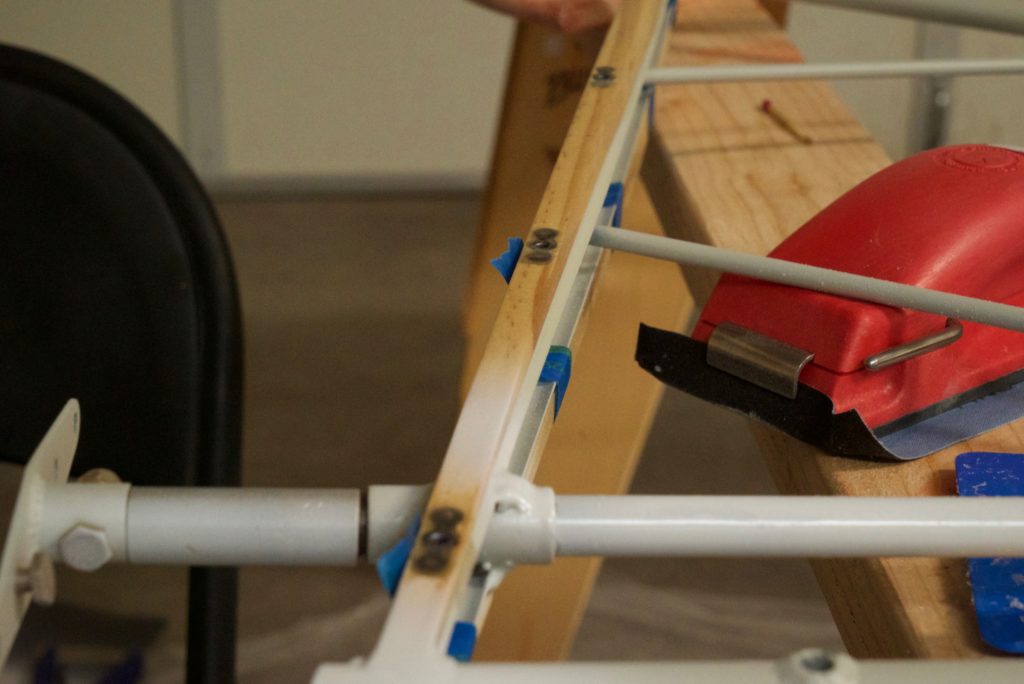

Paint Booth

Finish Covering Tail Feathers

Fairing Nut Plates

Tapes

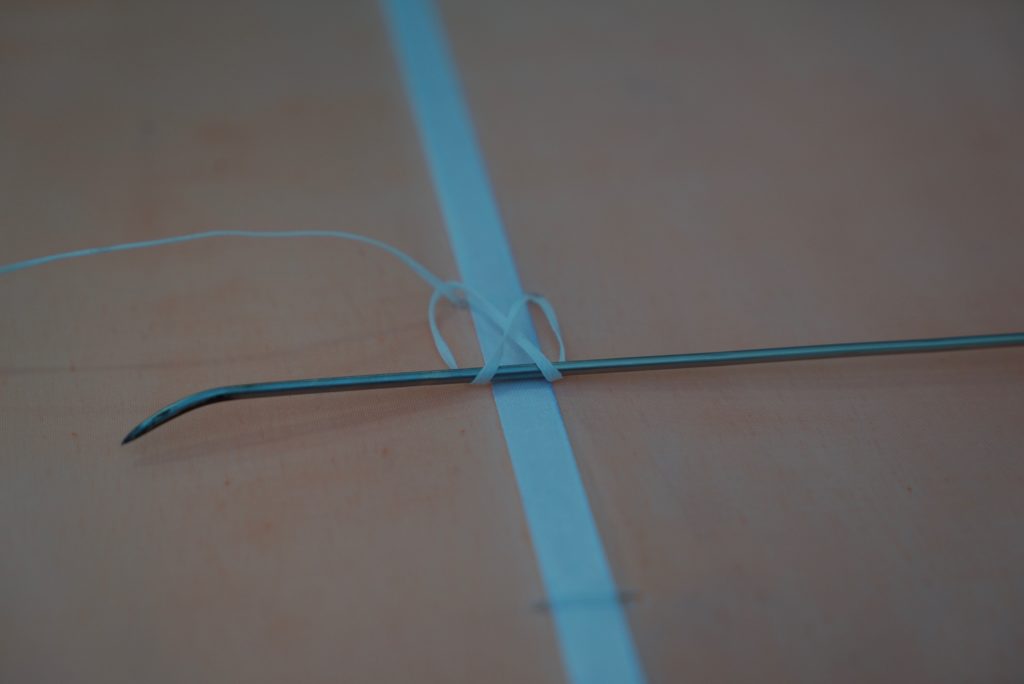

Rib Stitching

Like I mentioned before, I took the EAA Sport Air workshop on covering. We got plenty of practice at rib stitching, but I got the book out and made sure I was doing it correctly. Once you get going it’s pretty easy.

I don’t have any pictures of it, but my youngest daughter Tori would sit below the elevator and pass the needle back up. This made things go substantially faster!

Tail Covering

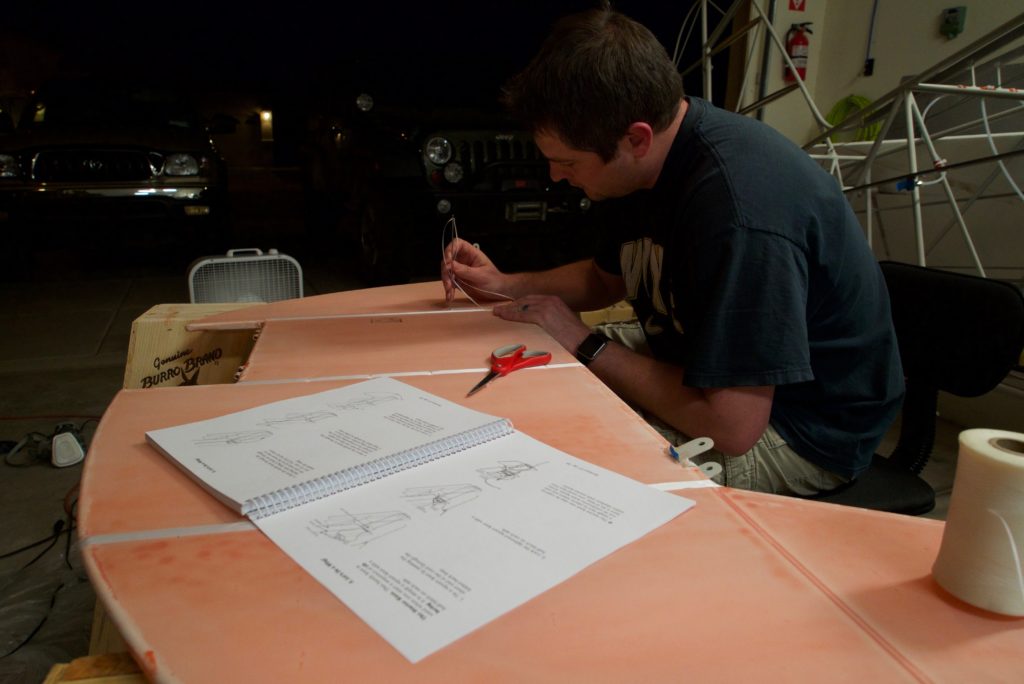

Since the PolyBrush, PolySpray, and PolyTone coatings are best applied when it’s below 85 degrees, I decided to get going on the fabric covering before summer. Otherwise I’ll have to wait until next winter to do it.

Above is a half covered elevator.

After covering, shrinking and the first coat of PolyBrush. It’s Pink!

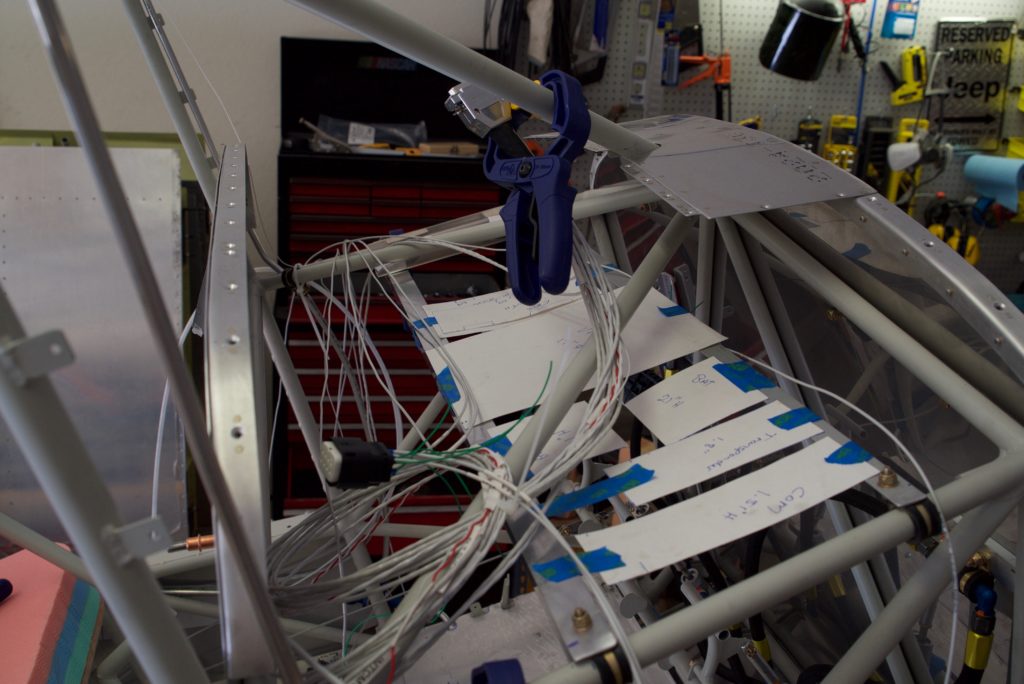

More wiring harness

I looked up the dimensions of each avionics competent and made their foot print out of poster board. Then started arranging them to my liking. This allowed me to start terminating wire and building the connectors at the proper locations.

You can see in this photo the first of 3 power plugs for the the Vertical Power VPX.