After a lot of research on oil coolers I decided on X-SERIES OIL COOLERS BY AIRFLOW SYSTEM. It also has a nice fiberglass cooling duct.

Category: Bearhawk 1175 Building Log

Building log of Bearhawk 1175

Air Box

I ordered an airbag from Aircraft Spruce. None of them fit my need exactly so, I bought the closest one and modified it. I had to cut off the two ports and add an extra one on the back. My air box will not need an overflow because it doesn’t receive ram air from the baffling. Instead the carb heat will collect ambient air from a partial shroud on the Vetterman exhaust.

Looking great!

Engine Baffling & Exhaust

More wiring and cargo doors

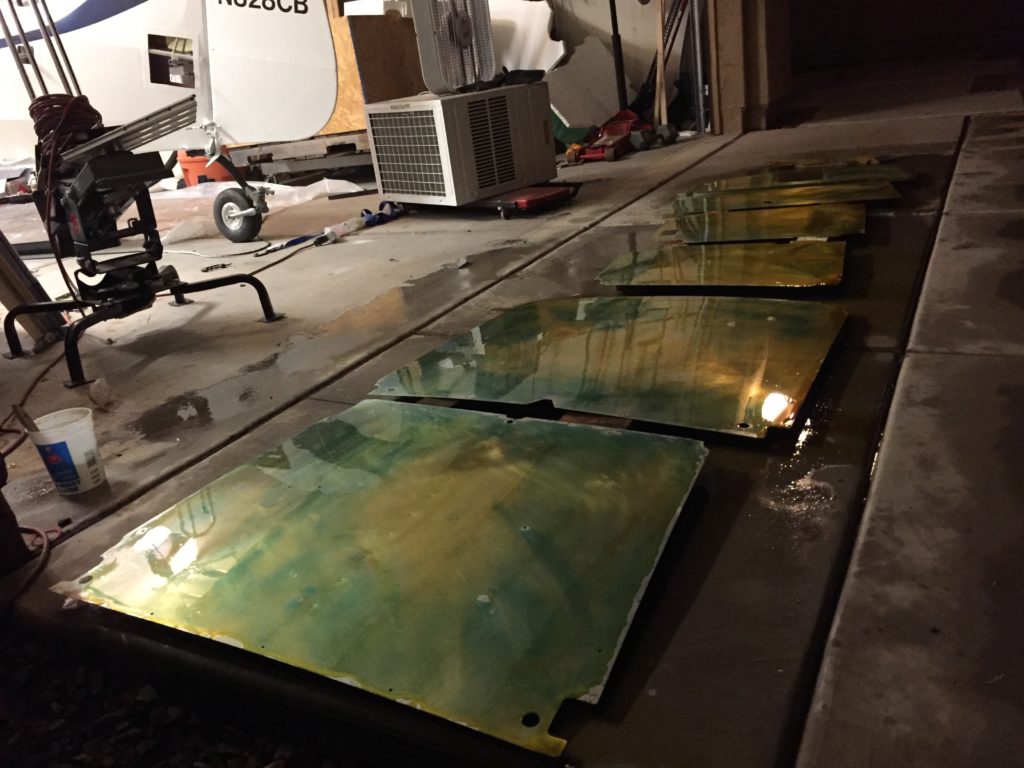

Flooring

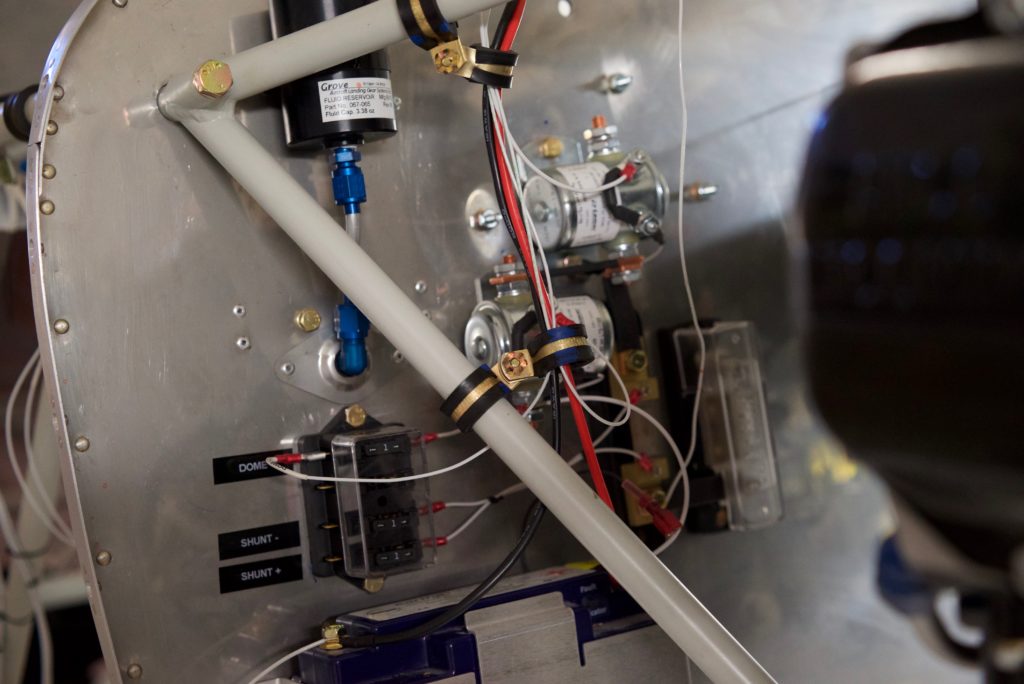

Starting the wiring

Over several days, I started designing and installing the main electrical components. In this picture you can see the two relays (starter and main), ANL Fuse, Shunt, Battery and the Fuse Box for the shunt wires and for a hot battery bus which will run the dome lights.

Here you can see the ELT control, parking brake, headset jacks, master switch, starter switch, throttle, switches and intercom have all been installed. Along with the paper mockups of the displays.

Seat upholstery

Rolling it outside

Hanging the engine

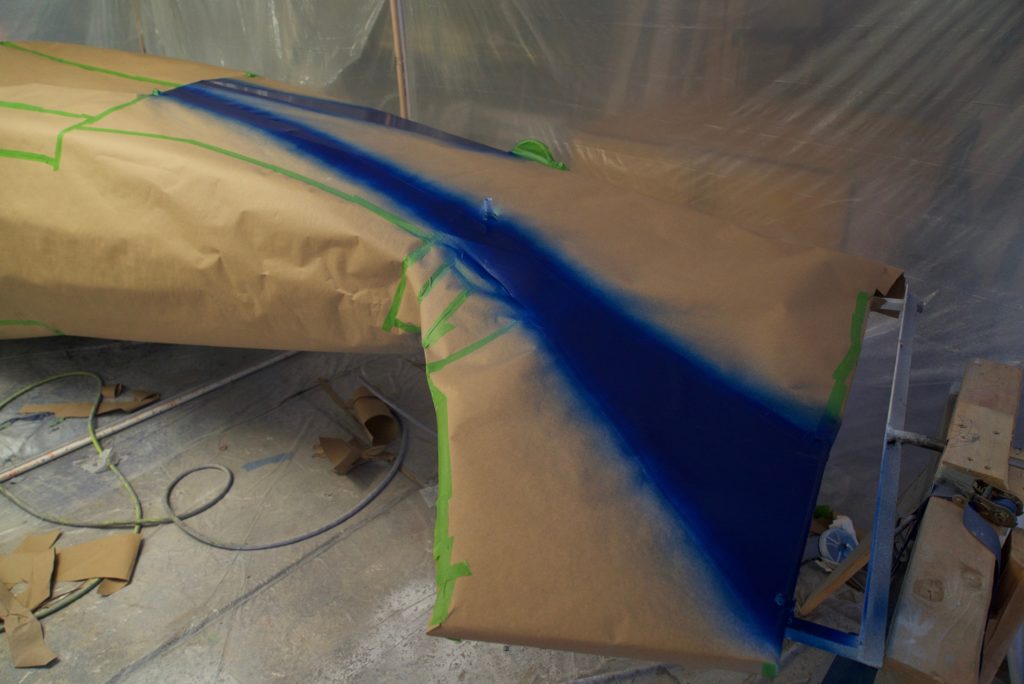

A little Blue

I wanted to do a traditional BearHawk paint job, but was warned about dark colors shrinking tapes in the hot AZ sun. So I scoured the internet for alternative paint schemes that would look nice but not have too much blue.

I started masking the lines for the blue trim. Took quite a while to get the lines the way I wanted them.

Next came the masking paper. I started with regular masking paper from Home Depot and wasn’t happy with how thin it was. So, I went back and got the heavy duty stuff. Basically the same as what paper grocery bags are made of.

With all the hard work done, the final painting was easy and a bit anticlimactic!

Looks nice!

Back up on wheels, I put the rudder on! The lines matched up! Yippee!