Taking a break from the airplane at the hangar I got to work on covering the ailerons and flaps. This is the exact same process as the rest of the fabric covering I’ve done so far.

It’s always cool to see how the fabric tightens right up with the iron.

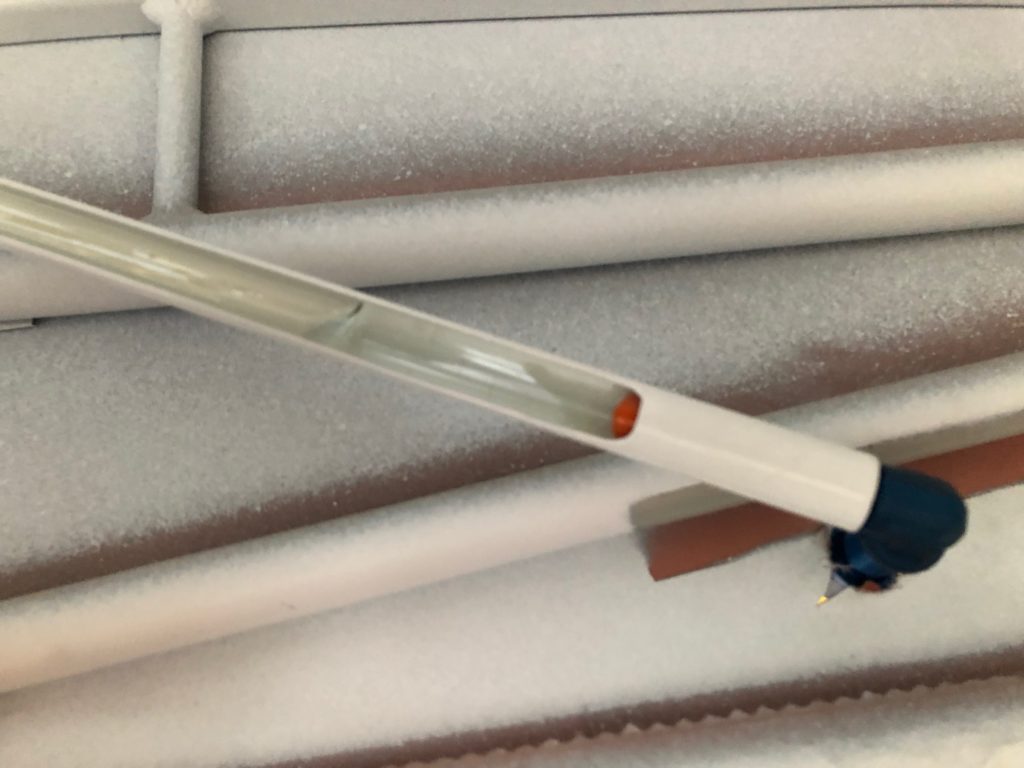

Making good progress they’re all polybushed and ready for rib stitching.

My trusty helper Tori came out to help poke holes and to chase the needle while I rib stitched.

After finishing all the tapes, another paint booth was erected. One coat in the morning and one in the evening through all the stages of PolyBrush, PolySpray and finally Poly Tone.